Product Buying Guides Product Buying Guides

-

Product Buying Guide

- Add an item to my portal

- Introducing our workwear recycling scheme

- Portal Video

- Return an item

- Special Item Request

- Clothing

- High VisibilIty

- Chemicals Protection

- Single Life Clothing

- Flame Retardant

- Chainsaw Protection

- Cut Protection

- Eye Wear

- Head Protection

- Hearing Protection

- Height Safety

- Respiratory Protection

- Footwear

- THE CONTEGO BUYING GUIDE TO SAFETY GLOVES

- First Aid

- Fire Safety

THE CONTEGO BUYING GUIDE TO SAFETY GLOVES

Introduction

Hands are vulnerable to a range of risks in the workplace. They must be protected against risks relating to cuts, lacerations and punctures, extreme heat and cold, chemical use and electrical hazards, as well as exposure to wet and dirty environments.

The failure to provide gloves or the appropriate type of gloves can lead to serious injuries or skin conditions, and have severe legal and reputational consequences for employers. Therefore, it is essential that your employees are provided with the right safety gloves.

Different tasks require different gloves and it is important that your employees are provided with the appropriate personal protective equipment. You should always base your choice of protective gloves on the most severe hazard that your employees will face.

There is a wide range of protective gloves available for a variety of applications . The use of these gloves is governed by a series of European industry safety standards. This buying guide provides an explanation of these standards and the performance you can expect from the gloves tested to these standards. It also explains the symbols used to convey this data.

Overall, this buying guide is designed to allow you to make an informed decision about the safety gloves you need to provide for your employees for the tasks that they undertake.

Key regulation and standards relating to protective gloves

The principal piece of legislation relating to the use of protective gloves in the workplace is Regulation (EU) 2016/425 on personal protective equipment. This replaced Directive 89/686/EEC in April 2018.

The safety gloves that you purchase and provide for your employees must comply with the new regulation. Gloves certified under the old directive should not be purchased or used.

In Regulation (EU) 2016/425, the use of personal protective equipment, including gloves, is categorised according to the risk to users. There are three categories of risk:Category I, Catgeory II and Category III.

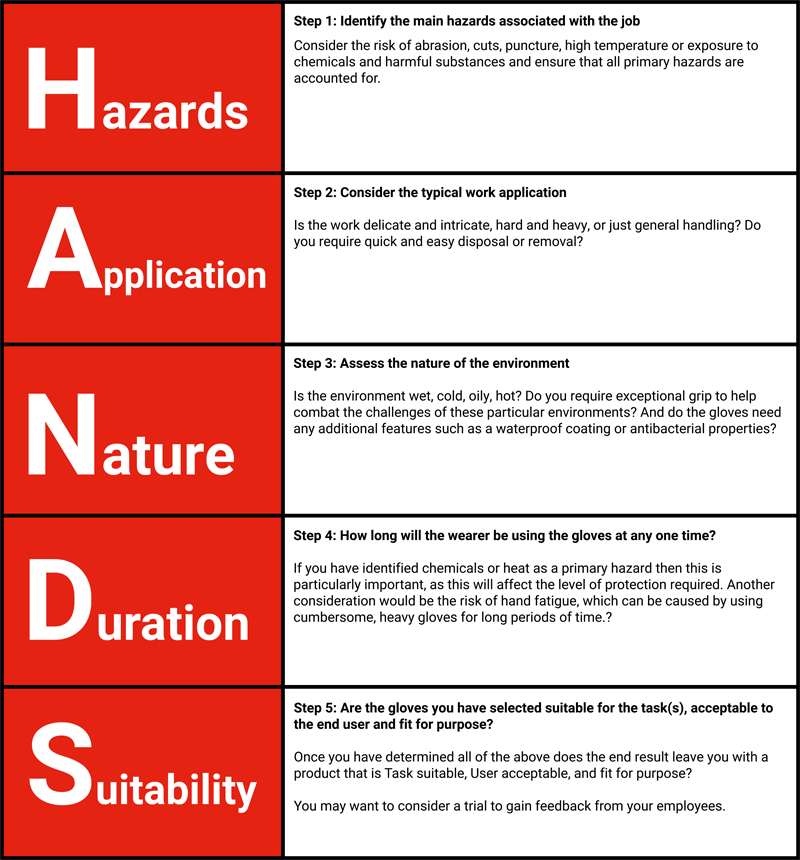

When selecting gloves, think HANDS

An overview of industry safety standards for gloves

Regulation (EU) 2016/425 is the basis for a range of European industry safety standards for protective gloves.

The safety gloves covered by these standards are classified in categories II and III of the regulation. The main standards that relate to the use of gloves in the workplace are:

In addition, there are workplace gloves that do not fall under

the control of these industry safety standards.

These gloves, such as

disposable latex, vinyl and nitrile gloves, are self-certified and are classified in risk

category I of Regulation (EU) 2016/425

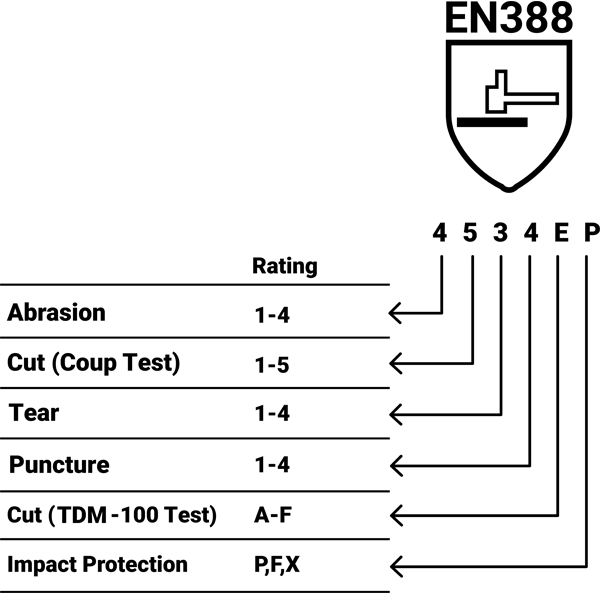

EN 388 – gloves providing protection against mechanical risks

EN 388 is the European safety standard for safety gloves that protect against mechanical risks. Mechanical risks are associated with the handling of rough or sharp objects that could harm the skin, such as glass, thin metal sheet and masonry blocks.

An EN 388 rating relates to abrasion, cut, tear and puncture resistance. Cut resistance is determined using either the Coup Test or the TDM- 100 Test.

The Coup Test, which is graded from 1 to 5, is carried out by moving a rotating circular blade across the material of a glove with a fixed force of 5 newtons. When the blade breaks through the material, the test is complete. (See page 5 for more information on this test).

The TDM-100 Test, which is graded from A to F, is based on the application of force in a single movement. The material of a glove is cut with a knife at a constant speed until the material breaks.

Abrasion, tear and puncture resistance are graded from 1 to 4. These ratings are shown with the EN 388 symbol that appears on a glove. (See page 6 for more information on these tests).

Also included in the standard and with the symbol is a rating related to impact protection (P: passed, F: failed and X: not tested). With regard to the X rating, if a glove is not designed to offer impact protection, it does not undergo this testing and as a result, is given the X grade.

Furthermore, if X appears anywhere on the EN 388 symbol, it means that the test in question has either not been performed or is not applicable.

It is important to note that according to this standard, mechanical risk does not include risk relating to moving machinery, where it could be considered dangerous to wear gloves, which could get caught in moving parts. EN 388 has been updated a number of times and the most recent version is EN 388: 2016+A1:2018.

EN 388 Classification

Ratings for gloves are displayed as per the image shown here. Below is an explanation of the tests carried and what the ratings confirm.

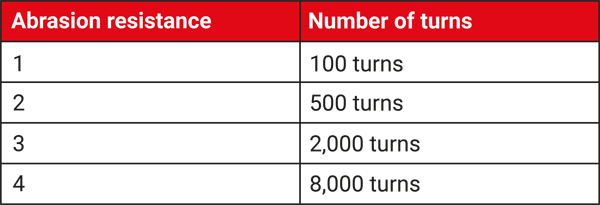

Abrasion resistance

This test is carried out by subjecting the material of a glove to abrasion by standard abrasive material under a range of pressures until a hole appears in the material. The pressure is measured in turns of the standard abrasive material. The higher the grade, the more resistant to abrasion a glove is.

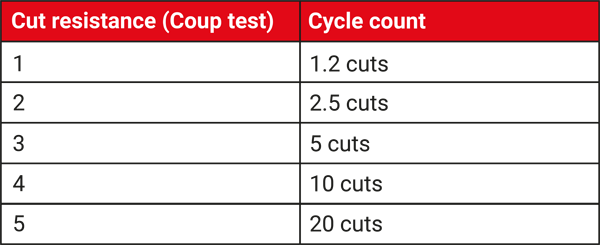

Cut resistance (Coup test)

The Coup test is carried out by moving a rotating circular blade across the material of a glove with a fixed force of 5 newtons. When the blade breaks through the material, the test is complete. The resistance grade given to a glove is determined by the blade cycle count required to cut through the material and by the condition of the blade. The higher the grade, the more protection against cutting a glove provides.

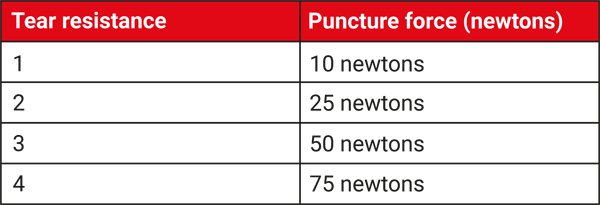

Tear resistance

This test is carried out by applying force to the material of a glove until it tears apart. The force is measured in newtons. The higher the grade, the more resistant to tearing a glove is.

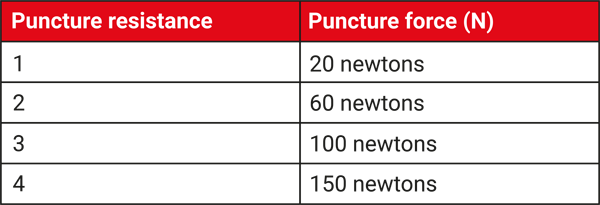

Puncture resistance

This test is carried out on the amount of force that is needed to puncture the material of a glove with a a solid probe, similar to the profile of a 6" (4.5mm) nail The force is measured in newtons. The higher the grade, the more resistant to puncture a glove is.

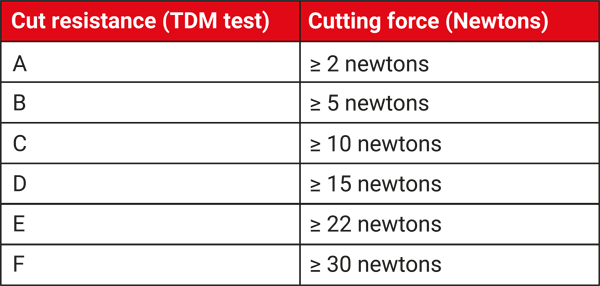

Cut resistance (TDM test)

The TDM test this is based on the application of force in a single movement, rather than in a circular movement as with the Coup test. The material of a glove is cut with a knife at a constant speed until the material breaks. The force is measured in newtons. The grade F indicates the highest level of protection against cutting.

Needlestick testing

It is important to note that the EN 388 Puncture Test is not an indicator of protection against from punctures and penetration by fine sharps, such as needles, thin wire or shards of glass. EN 388 does not currently test for this type of resistance. These gloves are tested to ASTM 2787-19 standard.

EN 420 – general requirements for protective gloves

EN 420 is the basic standard for a quality safety glove. All safety gloves that protect against hazard must conform to this standard and carry the symbol. The standard has been updated a number of times and the most recent version is EN 420: 2003+A1:2009.

The standard outlines the general requirements for safety gloves and its scope is considerable. The main areas are requirements for innocuousness, anti-static and water vapour and packaging and instructions.

Innocuousness

-

A glove is tested to ensure that it is comfortable to wear

and does not cause harm to the wearer. When you see EN 420 on a glove, it

means it has been manufactured to European sizing standards.

-

The dexterity of the glove is also tested. The smaller an

item that can be picked up using a glove, the higher dexterity grade it

receives.

- In addition, all gloves are checked for compliance with standards relating to pH value. The gloves must have a pH value of between 3.5 and 9.5.

Electrostatic and water vapour

If a glove is electrostatic or resistant to water vapour, it must be subjected to further testing.

Packaging and instructions

The packaging or instructions that come with a glove are required to include the following:

- The name of the manufacturer

- The size of the glove

- The relevant EN standard symbols

- The address of the manufacturer or representative

- The intended application

- If relevant, if protection is for a specific area of the hand

- Care and storage instructions

- Substances known to cause allergies

EN 374 – gloves providing protection against chemical and micro-organism risks

Safety gloves used in the handling of chemicals and micro-organisms must meet the requirements of EN 374. The latest version of the standard is EN 374:2016.

This safety standard has considerable scope and covers the use of a range of chemicals,taking into account factors such as permeability, shrinkage and breakthrough time.

As a result, the standard has several parts. The following parts are relevant for gloves, such as butyl chemical gloves and industrial neoprene gloves.

EN 374-1 – protection against dangerous chemicals and micro-organisms

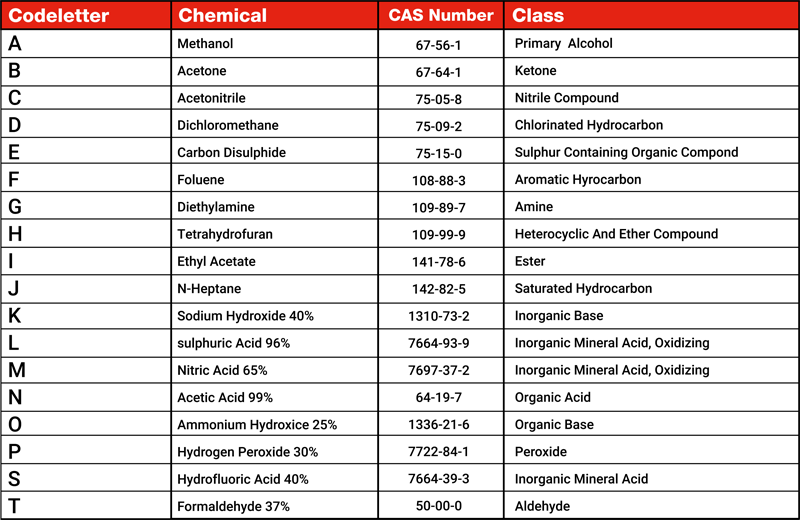

According to EN 374-1, gloves are tested for the protection they provide against 18 chemicals. The chemicals have code letters, from A to T, and CAS numbers, which are unique numbers used to identify chemicals.

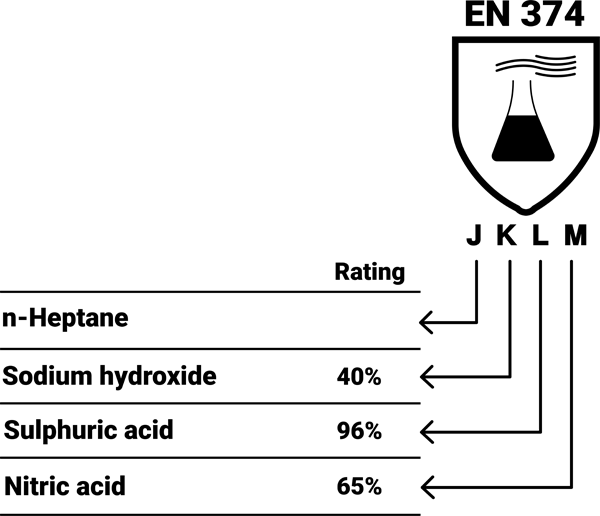

EN 374 Classification

The standard also classifies gloves as Type A, Type B or Type C, depending on the number of chemicals they protect against and their performance level.

Type A: safety gloves that provide permeation resistance of at least 30 minutes for at least 6 test chemicals

Type B: safety gloves that provide permeation resistance of at least 30 minutes for at least 3 test chemicals

Type C: safety gloves that provide permeation resistance of at least 10 minutes for at least 1 test chemicals

Most safety gloves that protect against chemicals are classed as Type A. The information relating to protection, both in terms of specific chemicals and performance, along with the EN 374 symbol, is marked on a glove. The rating figure for each chemical, presented as a percentage figure, refers to the strength of the chemical used for the test.

For example: The latest version of the standard is EN 374- 1:2016+A1:2018.

EN 374-2 – Protective gloves against dangerous chemicals and micro-organisms

Part 2: Determination of resistance to penetration

The latest version of the standard is EN 374-2:2019.

EN 374-4 – Protective gloves against chemicals and micro-organisms

Part 4: Determination of resistance to degradation by chemicals

EN 374-5 – Protective gloves against dangerous chemicals and micro-organisms

Part 5: Terminology and performance requirements for micro-organisms risks

This part of the standard relates to protection against bacteria and fungi. If a glove offer this type of protection, it displays the following symbol.

The latest version of the standard is EN 374:2016.

EN 16523-1:2015 – Determination of material resistance to permeation by chemicals

Part 1: Permeation by liquid chemical under conditions of continuous contact

This standard has replaced BS EN 374-3.

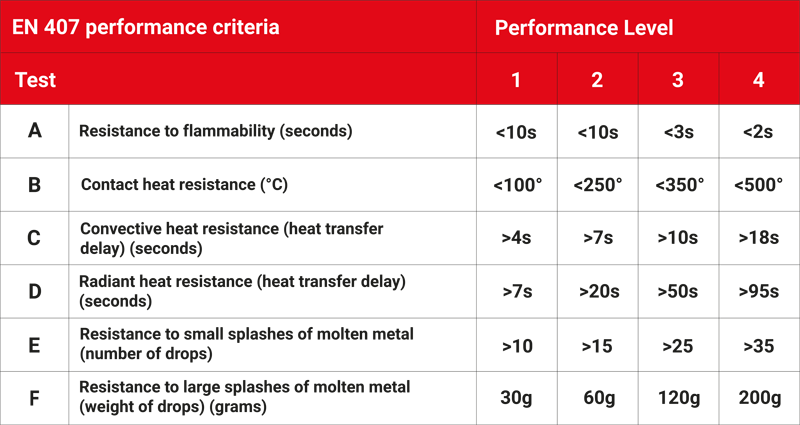

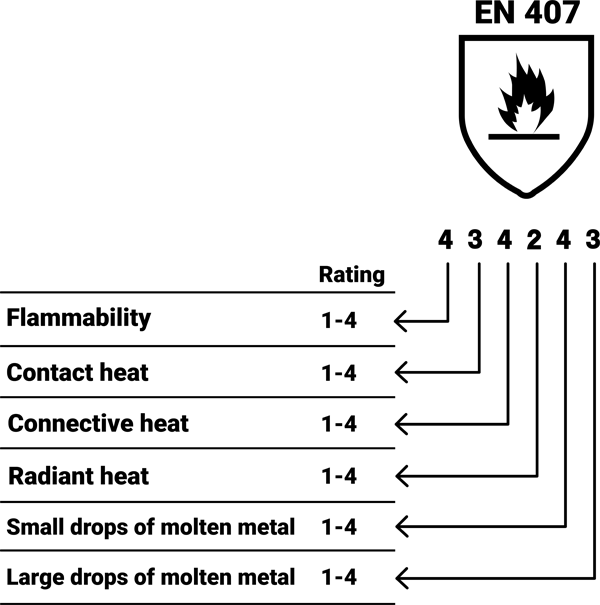

EN 407 – gloves providing protection against thermal risks

EN 407 is the European safety standard for safety gloves that protect against heat and/or fire . The standard has been updated a number of times and the most recent version is EN 407: 2020-TC.

The standard sets out the nature of protection provided by a glove and a performance level relating to this protective capability. There are six performance categories (A to F), with performance ratings ranging from 0 to 4. (with 4 the highest).

When purchasing gloves that protect against heat and/or fire, such as terry cotton wrist gloves, Kevlar gloves and foundry gloves, the EN 407 symbol will be displayed on the glove, along with a six-digit number that relates to the category of protection and the relevant performance level.

EN 407 - The six tests and related performance levels

A. Resistance to flammability (performance level 0-4)

This is based on the length of time the material continues to burn and glow after the source of ignition is removed. The seams of the glove should not come apart after an ignition time of 15 seconds.

B. Contact heat resistance (performance level 0-4)

This is based on the temperature range (100- 500°C) at which the user will feel no pain for at least 15 seconds.

C. Convective heat resistance (performance level 0-4)

This is based on the length of time the glove is able to delay the transfer of heat from a flame. A performance level is only mentioned if a performance level of 3 or 4 is obtained in the flammability test.

D. Radiant heat resistance (performance level 0-4)

This is based on the length of time the glove is able to delay the transfer of heat when exposed to a radiant heat source. A performance level is only mentioned if a performance level 3 or 4 is obtained in the flammability test.

E. Resistance to small splashes of molten metal (performance level 0-4)

This relates to the number of molten metal drops required to heat the glove sample to a given level. A performance level is only mentioned if a performance level

F. Resistance to large splashes of molten metal (performance level 0-4)

This relates to the weight of molten metal required to cause smoothing or pin-holing across a simulated skin placed directly behind the glove sample. The test is failed if metal droplets remain stuck to the glove material or if the specimen ignites.

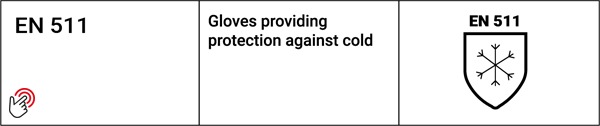

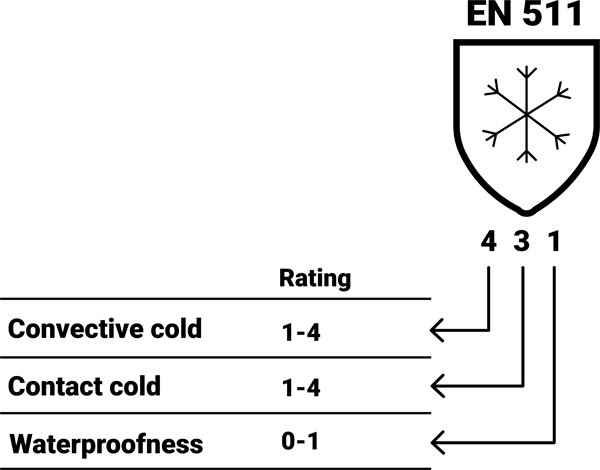

EN 511 – gloves providing protection against cold

EN 511 is the European safety standard for safety gloves that protect against extreme cold , which is defined as convective and contact cold down to -50°C. The standard sets out the nature and degree of protection provided by gloves, including thermal gloves, waterproof thermal gloves and leather thermal gloves.

There are three protection categories (A, B and C) with performance ratings. The information relating to the protection provided and the performance level is included below the EN 511 symbol that is displayed on the glove.

The three protection categories are:

A. Convective cold resistance (performance level 0-4):

based on the thermal insulation properties of the glove that are obtained by measuring the transfer of cold via convection

B. Contact cold resistance (performance level 0-4):

based on the thermal resistance of the glove material when exposed to contact with a cold object

C. Waterproofness:

0 is displayed if there is water penetration after 30 minutes of exposure; 1 is displayed if no water penetration has occurred

The standard has been updated a number of times and the most recent version is EN 511: 2006.

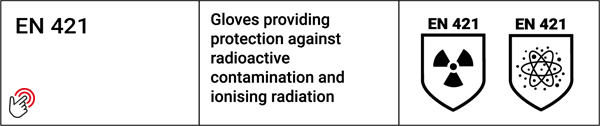

EN 421 – gloves providing protection against radioactive contamination and ionising radiation

EN 421 is the European safety standard for safety gloves that protect against radioactive contamination and ionising radiation. The latest version of the standard is EN 421:2010.

Gloves that provide protection against radioactive contamination will display the following EN 421 symbol (the glove has to be liquid-proof and needs to pass the penetration test defined in EN 374).

Gloves that provide protection in containment enclosures have to have high resistance to permeability of water vapour.

Materials may be modelled by their behaviour in relation to ozone cracking. This test is optional and can be used as an aid to selecting gloves that require resistance to ionising radiation.

Gloves that provide protection against ionising radiation will display this EN 421 symbol.

The glove has to contain a certain amount of lead, which is quoted as lead equivalence. The lead equivalence must be marked on each glove.

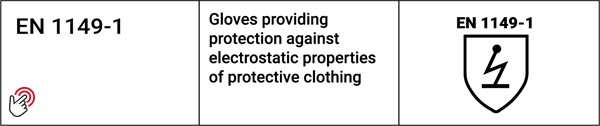

EN 1149-1 – electrostatic properties of protective clothing

EN 1149-1 is the European safety standard for protective clothing, including safety gloves, that are designed to provide electrostatic dissipation for preventing incendiary discharge.

The standard sets out the nature and degree of electrostatic resistivity and electrical resistance provided by a glove. Gloves that provide this protection will display the EN 1149-1 symbol.

These types of gloves are commonly used in environments in the gas, automotive, shipbuilding and chemical industries, on oil platforms and in clean rooms, electronics laboratories and industrial laundries.

Directive 2002/72 EC – food compatibility

Directive

2002/72 EC sets out the conditions and restrictions that all plastic

materials and objects, including gloves, must comply with if they are intended

to come into contact with foods.

Directive

2002/72 EC sets out the conditions and restrictions that all plastic

materials and objects, including gloves, must comply with if they are intended

to come into contact with foods.

Gloves that provide this protection and adhere to this regulation, such as single-use food handling gloves, reusable food handling gloves and cut-resistance food handling gloves, will display the Directive 2002/72 EC symbol.

How to choose the appropriate gloves for your employees

The information contained in this buying guide is designed to help you choose the right safety gloves when placing an order for your workforce.

By using this information and taking these steps, you will ensure that your company is fully compliant with all the relevant industry standards and that your employees can do their jobs safely, efficiently and to the highest standard.

Looking for industry-certified safety gloves? Check out our range today

The friendly and expert team at Contego Safety Solutions is always on hand to give advice and guidance on the right PPE and protective clothing for your needs. Contact us now on 0800 122 3323 or sales@contegosafety.co.uk to discuss your requirements.

This site uses cookies to store information on your computer. See our cookie policy for further details on their usage and how to block them.

Agree