Product Buying Guides Product Buying Guides

-

Product Buying Guide

- Add an item to my portal

- Introducing our workwear recycling scheme

- Portal Video

- Return an item

- Special Item Request

- Clothing

- High VisibilIty

- Chemicals Protection

- Single Life Clothing

- Flame Retardant

- Chainsaw Protection

- Cut Protection

- Eye Wear

- Head Protection

- Hearing Protection

- Height Safety

- Respiratory Protection

- Footwear

- THE CONTEGO BUYING GUIDE TO SAFETY GLOVES

- First Aid

- Fire Safety

Hi Vis Buying Guide 2022

THE CONTEGO BUYING GUIDE TO HI-VIS WORKWEAR

Introduction

The purpose of high-visibility (hi-vis) workwear is to visually signal the presence of the wearer in work environments where there is a potential risk to their safety. By wearing hi-vis clothing, workers become highly visible to other workers and people, including those operating heavy machinery and vehicles.The failure to provide hi-vis clothing or the appropriate type of hi-vis workwear can lead to serious accidents, injuries and fatalities, and can have severe legal and reputational consequences for employers. Therefore, it is essential that your employees are provided with the right hi-vis workwear.

There is a wide range of hi-vis workwear available for a variety of tasks and environments. The use of this personal protective clothing is governed by one main industry safety standard, EN ISO 20471:2013. There is also a supplementary standard that applies solely to the use of hi-vis workwear in the rail industry, RIS 3279-TOM.

Overall, this buying guide provides an explanation of these standards and the performance you can expect from the hi-vis workwear tested to these standards. It also explains the codes used to convey this information.

The role of risk assessments in selecting the right hi-vis workwear

When purchasing hi-vis workwear for your employees, it is recommended that you refer to a recent risk assessment of the workplace environments in which your employees are working. If a risk assessment does not exist, one should be carried out.

Carrying out a risk assessment provides a clear understanding of the hazards that the hi-vis workwear you choose needs to provide protection against. This will allow you to select the appropriate hi-vis workwear and ensure that your organisation complies with all relevant health and safety rules and other industry regulations.

Key industry standards relating to hi-vis workwear

The main industry standard relating to the design of hi-vis workwear in the workplace is EN ISO 20471:2013.

EN ISO 20471:2013-certified hi-vis workwear is used by workers in a wide range of industries, including the aerospace, construction, food, forestry and highway sectors.

EN ISO 20471:2013 sets out strict requirements with regard to the performance of hi-vis workwear, in particular in relation to tensile strength, thermal resistance and dimensional stability, and regarding the amount of colour bleeding between reflective strips and the fluorescent and contrast materials

In addition, the RIS 3279-TOM Railway Group Standard relates solely to the use of hi-vis workwear by the railway industry.

EN ISO 20471:2013 – the high-visibility clothing standard

EN ISO 20471:2013 is the main standard for hi-vis workwear. All hi-vis workwear must conform to this standard and must be labelled with the EN ISO 20471:2013 badge.There are three classifications of EN ISO 20471:2013-certified workwear. These classifications are based on the level of visibility they provide and the risk posed to the wearer by the environment they are working in.

The classification should be visible on the EN ISO 20471:2013 badge that features on the hi-vis workwear.

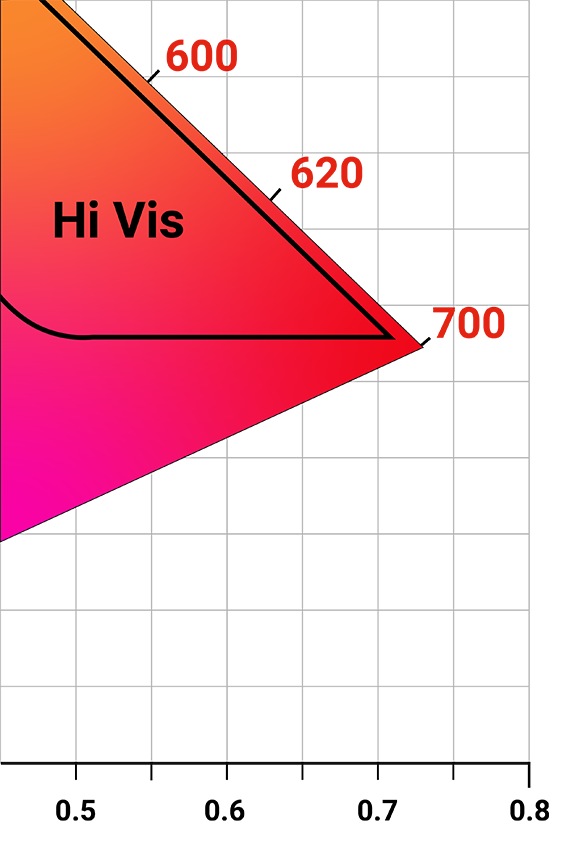

Approved High-Visibility Colours

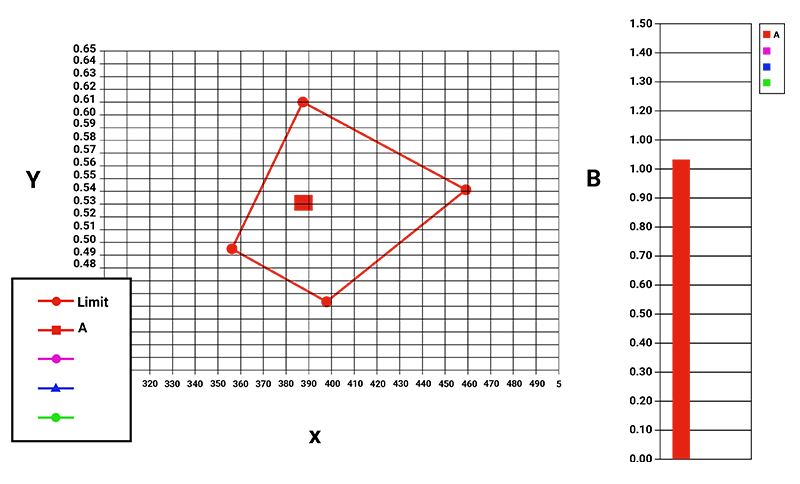

Certified hi-vis workwear must conform to specific colour and luminance requirements as set out in EN ISO 20471:2013. The colours need to be within a range defined by the following coordinates:

MISSING TABLE image not present in drive

EN ISO 20471:2013 Class 1

Hi-vis workwear in this class offers the lowest level of visibility.

It features a minimum of 0.14m2 of fluorescent material and 0.10m2 of reflective strip material.

This hi-vis clothing is suitable for off-road work.

EN ISO 20471:2013 Class 2

Hi-vis workwear in this class offers a medium level of visibility.

It features a minimum of 0.50m2 of fluorescent material and 0.13m2 of reflective strip material.

This hi-vis clothing is suitable for work on roads where the speed limit is 40mph or less.

EN ISO 20471:2013 Class 3

Hi-vis workwear in this class offers the highest level of visibility. It features a minimum of 0.80m2 of fluorescent material and 0.20m2 of reflective strip material. This hi-vis clothing is suitable for all work on highways.

Individual pieces of EN ISO 20471:2013 Class-3 certified hi-vis workwear are available to purchase for workers.

A Class 3 level of hi-vis workwear can also be achieved by wearing multiple pieces of hi-vis clothing that are rated as joint certified and that together have an amount of fluorescent material and reflective strips that meets Class 3 requirements.

If hi-vis workwear is rated as joint certified, this will be indicated on the label inside the piece of hi-vis clothing.

RIS 3279-TOM – the high-visibility clothing standard for the rail industry

RIS 3279-TOM is the standard for hi-vis workwear for the rail industry.

It applies only to the rail industry and is based on the EN ISO 20471:2013 standard.

All RIS 3279-TOM-hi-vis clothing must as a minimum comply with EN ISO 20471:2013 Class 2 requirements. EN ISO 20471:2013 class 1 garments cannot be RIS 3279-TOM-certified hi-vis workwear.

RIS-3279-TOM-hi-vis clothing colour specifications RIS-3279-TOM-certified hi-vis workwear must conform to specific colour and luminance requirements as set out in EN ISO 20471:2013. With regard to the colour range, in order to guarantee a specific orange colour and to avoid choosing a colour at the red end of the spectrum, the standard details the precise chromaticity coordinates to be used for RIS-3279-TOM-certified hi-vis workwear: fluorescent orange X:0588 and Y:0371, with a luminance factor of at least 0.4. The permitted tolerance for colour is stipulated in EN ISO 20471:2013. There is no tolerance framework for the luminance factor.

Key components of hi-vis workwear

Hi-vis workwear has three main components, all of which must comply with the stipulations set out in EN ISO 20471:2013. The components are:

- Fluorescent material: this increases wearer visibility during both the day and the night

- Reflective strips: these need a light source to function (they are retro-reflective). They increase wearer visibility during darker periods of the day and are vital to ensuring wearer visibility at night

- Contrast material: this is less sensitive to dirt and dust than fluorescent material and reflective strips, and its presence helps to ensure the functionality of these other components. It is usually positioned where dirt and dust build-up most commonly occurs – the end of sleeves, ankle and knee sections and across the abdomen

Key considerations when wearing hi-vis workwear

It is important that hi-vis workwear is worn properly. If it is not worn properly, there is a risk that it will not comply with the EN ISO 20471:2013 standard.

There are minimum requirements relating to the area of fluorescent material and reflective strips on hi-vis workwear. As such, care should be taken not to reduce the visible area of fluorescent material and reflective strips below that set out in the standard. This means that::

- Adjusting and tailoring hi-vis workwear must be approached with caution

- Hi-vis trousers should not be tucked into safety boots

- Non-hi-vis clothing that is worn must not cover the fluorescent material and reflective strips

- Branding or personalising hi-vis workwear should not reduce the area of the clothing covered by fluorescent material and reflective strips

In addition, EN ISO 20471:2013 sets out strict requirements with regard to the performance of hi-vis workwear, in particular in relation to tensile strength, thermal resistance and dimensional stability, and regarding the amount of colour bleeding between reflective strips and the fluorescent and contrast materials.

Key considerations when maintaining hi-vis workwear

It is important that hi-vis workwear is maintained properly. If it is not maintained properly, there is a risk that it will not comply with the EN ISO 20471:2013 standard.

Why following washing guidelines is important

Hi-vis workwear should always be washed according to the manufacturer’s instructions, which can be found inside the clothing, and unless stated, any garment should be washed a maximum of 25 times according to the manufacturer’s instructions, after which it should be replaced.

The failure to follow these guidelines could cause the colour of the garment to fade and the reflective quality of the reflective strips to deteriorate. In the event of this type of fading and damage, there is a risk that the garment would no longer comply with the EN ISO 20471:2013 standard and that the visibility of the garment would be reduced, affecting its performance and endangering the wearer.

With regard to the colour of hi-vis workwear, the colour of a garment must remain with specific parameters for the clothing to be compliant with EN ISO 20471:2013. If hi-vis workwear is washed at too high a temperature or if it is over-washed, there is a risk that the colour of the garment may fade and no longer meet the necessary colour specifications.

With regard to the deterioration of the reflective strips, washing at too high a temperature and over-washing also carries the risk of affecting the reflective quality of this area of the clothing, which could result in the clothing not producing the necessary level of reflectivity.

Properly maintaining hi-vis workwear also applies to ensuring that garments are clean and free from blemishes and stains. If fluorescent material and reflective strips are obscured by dirt or grease, the garment no longer conforms with the EN ISO 20471:2013 standard.

With this in mind, to prolong the life of hi-vis workwear, it is recommended that each worker is given two pieces of each type of hi-vis clothing.

How to choose the appropriate hi-vis workwear for your employees

A wide range of this EN ISO 20471:2013-certified hi-vis clothing is available in three EN ISO 20471:2013-approved fluorescent colours: yellow, orange and red.

The information contained in this buying guide to hi-vis workwear is designed to help you choose the right hi-vis workwear when placing an order for your workforce.

Different tasks and environments require different hi-vis workwear and it is important that your employees are provided with the appropriate personal protective equipment. You should always base your choice of hi-vis workwear on the most severe hazard that your employees will face.

By using this information and taking these steps, you will ensure that your company is fully compliant with all the relevant industry standards and that your employees can do their jobs safely, efficiently and to the highest standard.

Looking for industry-certified hi-vis workwear? Check out our range today

The friendly and expert team at Contego Safety Solutions is always on hand to give advice on personal protective equipment and clothing. Contact us now on 0800 122 3323 or sales@contegosafety.co.uk to discuss your needs.

This site uses cookies to store information on your computer. See our cookie policy for further details on their usage and how to block them.

Agree